Types of Pipelines

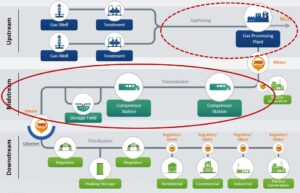

Gathering

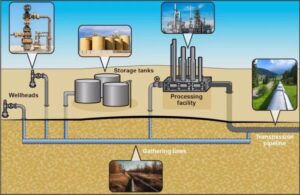

An oil and gas gathering pipeline system is a network of pipelines that move crude oil and natural gas from well sites to a central collection point. The central point can be a processing plant, storage facility, compressor station, shipping point, or larger transmission pipeline.

Here are some characteristics of oil and gas gathering pipelines:

- Size – gathering lines are smaller in diameter than transmission lines.

- Pressure – gathering lines typically operate at relatively low pressures.

- Length – gathering lines are usually short in length.

- Type – there are two types of gathering systems: onshore and offshore. Onshore systems are easier to construct and maintain, while offshore systems face unique challenges like high pressures and deep-water conditions.

- Regulation – the Pipeline and Hazardous Materials Safety Administration (PHMSA) regulates most gathering lines.

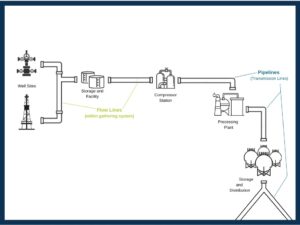

Transmission

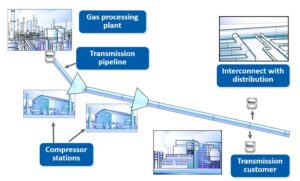

An oil and gas transmission pipeline system is a network of pipelines, equipment, and facilities that transport oil and gas from gathering areas to storage, processing, or distribution facilities:

- Pipelines – transmission pipelines are large-diameter pipes that can range from several inches to several feet in diameter. They are usually made of steel, but plastic has also been used.

- Equipment – transmission pipeline systems include pumps, compressors, valves, breakout tanks, and storage tanks.

- Facilities – transmission pipeline systems include refining and processing facilities.

- Pressure – transmission pipelines can operate at a range of pressures, from relatively low to over 1,000 pounds per square inch (psi).

- Configuration – transmission pipelines are often designed in a grid or trunkline system.

- Distance – transmission pipelines are designed to transport large volumes of oil and gas over long distances.

Transmission pipelines are generally considered safer and cheaper than ground transportation.

Distribution

An oil and gas distribution pipeline system is a network of pipelines that transport oil and gas products from transmission lines to homes, businesses, and industrial facilities.

Distribution systems are made up of two types of lines:

- Main distribution lines – Larger lines that move products close to cities

- Service distribution lines – Smaller lines that connect main lines into homes and businesses

Distribution pipelines are typically made of smaller line pipes, usually 2–24 inches in diameter. As the pipe gets closer to the end user, the pressure decreases and the pipe size decreases. For example, the pressure near the transmission line is typically 60 psi, while the pressure at a home or small business is typically 1 psi.

Pressure-reducing valves (PRVs) are an important part of distribution systems. PRVs automatically adjust the flow of gas to maintain a constant output pressure. This helps ensure a reliable supply of gas to appliances and heating systems.

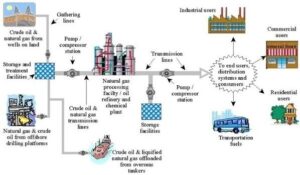

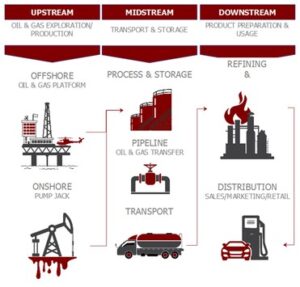

Upstream

An upstream pipeline system is a network of pipelines used to transport natural gas or crude oil from production facilities to a processing plant, terminal, or landing terminal.

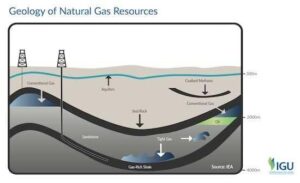

The upstream sector of the oil and gas industry is also known as the exploration and production (E&P) sector. It involves activities such as:

- Exploration – locating areas with a high potential for resources, such as those with known petroleum deposits or favorable geology

- Drilling – using geophysical and geochemical analysis to test the potential of a resource with exploratory wells

- Production – constructing wells and extracting the resource

Midstream

A midstream pipeline system is a part of the oil and gas industry that moves, stores, and distributes energy products like crude oil and natural gas. Midstream pipelines are a key part of the infrastructure that connects the upstream and downstream segments of the industry.

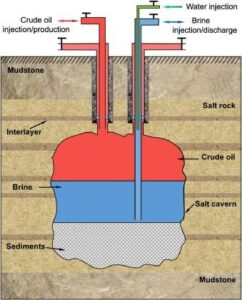

Midstream pipelines are part of a larger midstream system that includes:

- Gathering – collecting production from wells or production facilities

- Processing – separating hydrocarbons into different components

- Treating – removing water or waste products

- Dehydration – removing water from the natural gas

- Compression – increasing the pressure of the natural gas

- Storage – keeping natural gas in underground reservoirs until it’s ready to be transported

- Transportation – moving natural gas and other energy products through pipelines, trucks, railways, and ships

- Marketing – delivering the energy products to end-use markets

Midstream pipelines are critical for transporting resources safely and efficiently over long distances.

Downstream

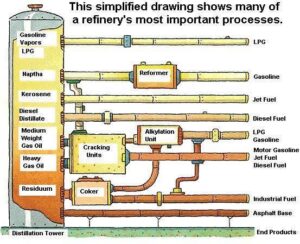

A “downstream pipeline system” in the oil and gas industry refers to the network of pipelines that transport refined oil and gas products, like gasoline, diesel, and jet fuel, from refineries to the final consumer markets, including gas stations and industrial facilities, essentially representing the final stage of the oil and gas production chain where the product is delivered to the end user.

Key points about downstream pipelines:

- Function – after crude oil is refined, the downstream pipeline system carries these refined products to distribution points where they can be accessed by consumers.

- Distinction from upstream and midstream – upstream involves exploration and extraction of oil and gas, while midstream focuses on transporting raw oil and gas from the wellhead to refineries; downstream is the final stage of delivery to the consumer.

Important aspects of a downstream pipeline system:

- Refinery connections – pipelines originate at refineries, where crude oil is processed into usable products.

- Distribution networks – these pipelines branch out to reach various distribution points like storage terminals and retail fueling stations.

- Smaller diameter pipes – compared to midstream pipelines, downstream pipelines are often smaller in diameter to accommodate the delivery of smaller volumes to various locations.

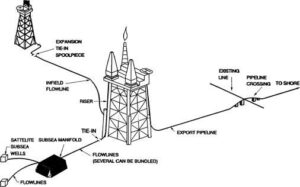

Flowline

An oil and gas flowline pipeline system is a network of pipelines that moves fluids and gas from the wellhead to processing facilities.

Function:

Flowlines transport fluids and gas from the wellhead to processing equipment, such as separation, treating, heating, dehydrating, compression, and pumping.

Location:

Flowlines are part of the gathering system, which takes petroleum and natural gas products from wells to processing facilities.

Design:

Flowlines are designed to handle varying pressure levels and may change in diameter to accommodate fluctuations in the flow rate of materials.

Temperature:

The design temperature of flowlines is normally decided based on the environmental conditions.

Maintenance:

Flowlines require regular inspection to prevent leaks and corrosion.

Safety:

Flowlines are often considered the safest method of transporting water, oil, and gas.

Feeder

An oil and gas feeder pipeline system is a small pipeline that moves refined or processed products from storage tanks and processing facilities to long-distance transmission pipelines.

Purpose: feeder pipelines transport refined products, such as crude oil, natural gas, or natural gas liquids, to transmission pipelines.

Size: feeder pipelines are typically six to 20 inches in diameter and five to 20 kilometers long.

Location: feeder pipelines are located downstream of processing facilities, after raw production has been processed.

Function: feeder pipelines ensure that the commodity meets the specifications of transmission pipelines.

Natural Gas

The gaseous mixture of hydrocarbons, primarily methane, that is transported through a network of underground pipes from its extraction source to consumers, allowing for large-scale distribution of this energy source for heating and other purposes; essentially, it’s natural gas being delivered via a pipeline system.

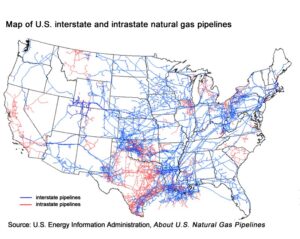

Key points about natural gas in a pipeline system:

- Composition – primarily composed of methane, with smaller amounts of other hydrocarbons like ethane and propane.

- Transportation method – pushed through pipelines under high pressure, allowing for efficient long-distance transport.

- Pipeline network – a complex system of interconnected pipelines including gathering lines (from production wells), transmission lines (long-distance transport), and distribution lines (delivering gas to end users).

- Regulation – subject to regulations by government agencies to ensure safe and reliable delivery.

Petroleum

“Petroleum” refers to any liquid hydrocarbon product derived from crude oil, including the raw crude oil itself, as well as refined products like gasoline, diesel, jet fuel, and heating oil, which are transported through pipelines from the extraction site to refineries and then to distribution points for consumer use; essentially, it encompasses all liquid forms of oil moved through a pipeline system.

Key points about petroleum in pipelines:

- Includes crude oil – the raw, unrefined oil extracted from the ground is considered petroleum within a pipeline system.

- Refined products – once crude oil is processed in a refinery, the resulting products like gasoline, diesel, and kerosene are also classified as “petroleum” when transported through pipelines.

- Transportation method – pipelines are the primary method for transporting large volumes of petroleum over long distances.

Oil

Oil is liquid petroleum, which includes crude oil and refined petroleum products, such as gasoline, diesel, and kerosene. Oil pipelines are used to transport oil from extraction sites to processing facilities and consumer markets.

There are three main types of oil pipelines:

- Gathering pipelines – collect crude oil or natural gas liquids from production wells

- Crude oil pipelines – transport crude oil to refineries

- Refined products pipelines – transport refined petroleum to storage or distribution stations

Oil pipelines are usually made of steel and are welded together. They are coated externally and protected cathodically to reduce corrosion. Additives are sometimes added to the oil to reduce corrosion and energy loss.

Water

Water pipelines is the flow of treated, potable water being transported through a network of pipes, typically from a water treatment plant to consumers, within a distribution system, including the main water lines and smaller branch lines that deliver water to individual homes and businesses; essentially, it’s the continuous movement of drinking water within a plumbing infrastructure designed to deliver it to its destination.

Key points about water pipeline systems:

- Function – to transport treated water from a source to users

- Components – includes large diameter “water mains,” which carry water over long distances, and smaller branch lines that connect to individual properties

- Regulation – water quality is monitored and regulated to ensure it meets safety standards